Lithography

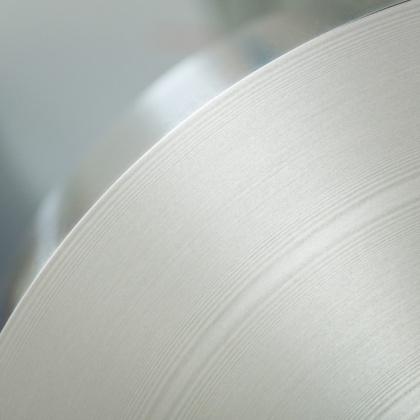

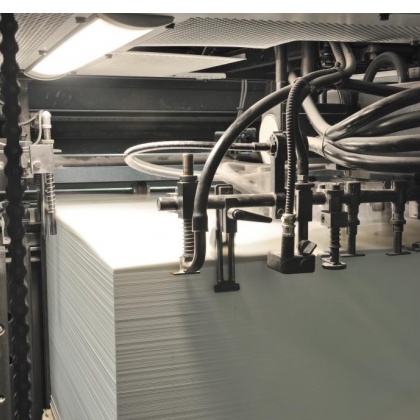

Bridgnorth Aluminium Ltd is passionate about producing perfectly finished lithographic quality aluminium, used as a substrate in the manufacturing of printing plates.

Why Bridgnorth Aluminium Ltd?

All of our processes have been carefully designed with surface criticality in mind.

Most of the aluminium rolling slabs that we process are sourced from our own casthouse; all material sourced externally is purchased from stringently approved suppliers. During the hot rolling process, surface cleanliness and material flatness are managed by sophisticated control systems. In order to achieve optimum mechanical properties and maximum on-press plate performance, coils are also batch-annealed in a fully computerised environment. The latest technology is used to control material flatness and thickness at the cold rolling stage and, on our finishing lines, coils are trimmed to the correct width, levelled and degreased. Surface inspection equipment is used to further control quality at this stage. At the inspection and packing stage, coils are visually inspected and the dimensional accuracy is checked. A laser measurement system verifies material flatness.

Lithography Process